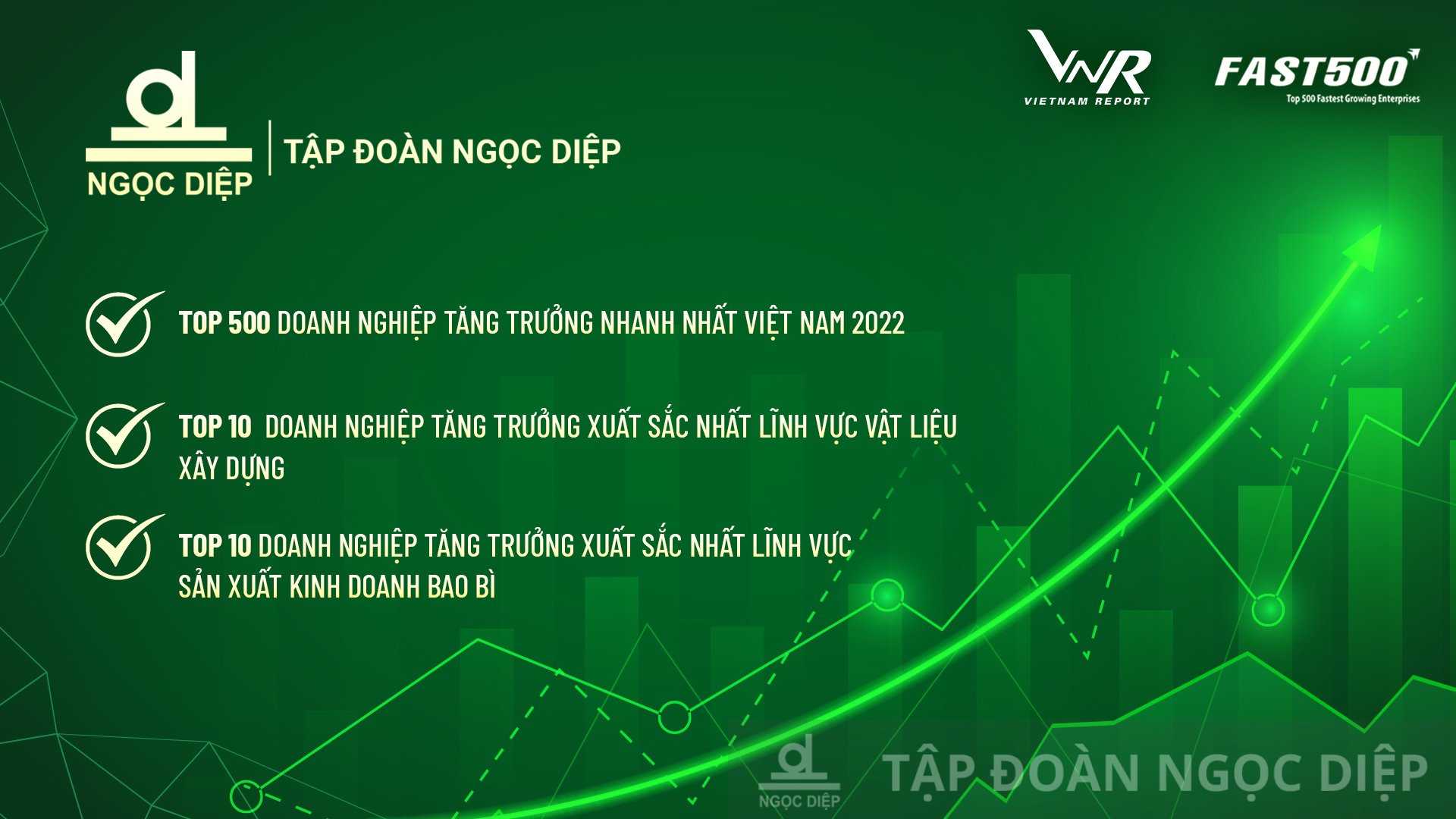

Ngoc Diep Group continues to be in the Top 500 Fastest Growing Enterprises in 2022

On April 22, VietNam Report and VietNamnet Newspaper held a ceremony to announce and honor the Top 500 fastest-growing enterprises in Vietnam in 2022 (FAST500). Accordingly, Ngoc Diep Group continues to be honored in the FAST500 Ranking in 2022.

The FAST500 Ranking in 2022 continues to recognize and honor Vietnamese enterprises with high growth and efficiency in the period 2017 – 2021. These are dynamic and typical enterprises with outstanding business achievements, have made an important contribution to the Vietnamese economy, opened up many opportunities and attracted strong investment resources, contributing to promoting Vietnamese business brands to the domestic and international business community.

Mrs. Hoang Thi Thai Hanh – Finance Director of Ngoc Diep Group received the title of Top 500 fastest growing enterprises in Vietnam 2022

With the outstanding development in production and business, strong and synchronous investment in production technology, expansion of scale and diversification of products to meet domestic and export markets are positive signs. shows the flexibility and innovation in Ngoc Diep Group’s strategic vision to achieve strong growth.

Ngoc Diep Group owns prominent brands in manufacturing and supplying construction materials such as: DINOSTAR Aluminum, NGOCDIEPWINDOW, Ngoc Diep Furniture and Ngoc Diep Packaging. Recently, DINOSTAR aluminum brand has reached the Top 5 most prestigious building materials in 2022 in the industry group: “Doors, profile panels, partitions: Aluminum glass, plastic, plaster”. Ngoc Diep Packaging achieved the Top 10 most prestigious paper packaging enterprises in 2021 (ranking voted by VietNam Report).

Mr. Bui Ngoc Duc – Production Director of Ngoc Diep Aluminum Joint Stock Company received the title of Top 5 most prestigious building materials in 2022

Facing the complicated developments of the Covid-19 epidemic, facing the slowing growth of the economy in general, Ngoc Diep Group flexibly adjusted its production and business plan, proactively supplied raw materials for the group’s chain of production plants, promoting research and development (R&D) activities to produce new products of outstanding quality to meet increasingly strict requirements of customers. .

To achieve strong growth results, Ngoc Diep Group has boldly invested in digital transformation 4.0 in corporate governance and operation. Typically: Enterprise Resource Planning (ERP) system: blockchain, big data, IOT, AI; CRM customer management system, HRM human resource management system … This is considered the foundation for creating competitive advantages and development of Ngoc Diep.

In the period of 2019-2021, Ngoc Diep Group has implemented many activities and solutions to share difficulties with employees and the community in the prevention of the Covid-19 pandemic, stabilizing lives, increasing income. for employees in the whole corporation.

Previously, Ngoc Diep Group has been honored at many major awards by the Government and prestigious organizations such as: Top 500 largest private enterprises in Vietnam, Top 500 most profitable enterprises in Vietnam. Nam, Top 10 prestigious paper packaging enterprises, many years in a row achieved National Brand, National Quality…

“It is not only a worthy recognition for the continuous efforts of Ngoc Diep Group, but also a motivation for the group to continue firmly on the development journey to conquer new heights”, a representative of the group said.

————————–

NGOC DIEP GROUP

THE PINNACLE OF QUALITY – CREATING THE FUTURE

Headquarters: 35 Hai Ba Trung Street – Hoan Kiem District – Ha Noi city

Tel: (+84) 24 3942 2828 – Fax: (+84) 24 3942 7840

Factory: Pho Noi A Industrial – Van Lam District – Hung Yen Province

Website: https://ngocdiep.vn/