Aluminium prices hit decade high on Guinea coup

Aluminium prices hit their highest levels in a decade on Monday as concerns grow about shortages following news of a coup in Guinea, the world’s largest reserves of bauxite, and production cutbacks in China, the world’s biggest producer.

A unit of Guinea’s military seized power and suspended the constitution, triggereing concerns about the supply of bauxite needed to make aluminium.

Guinea has the world’s largest reserves of bauxite, the globe’s main source of aluminum.

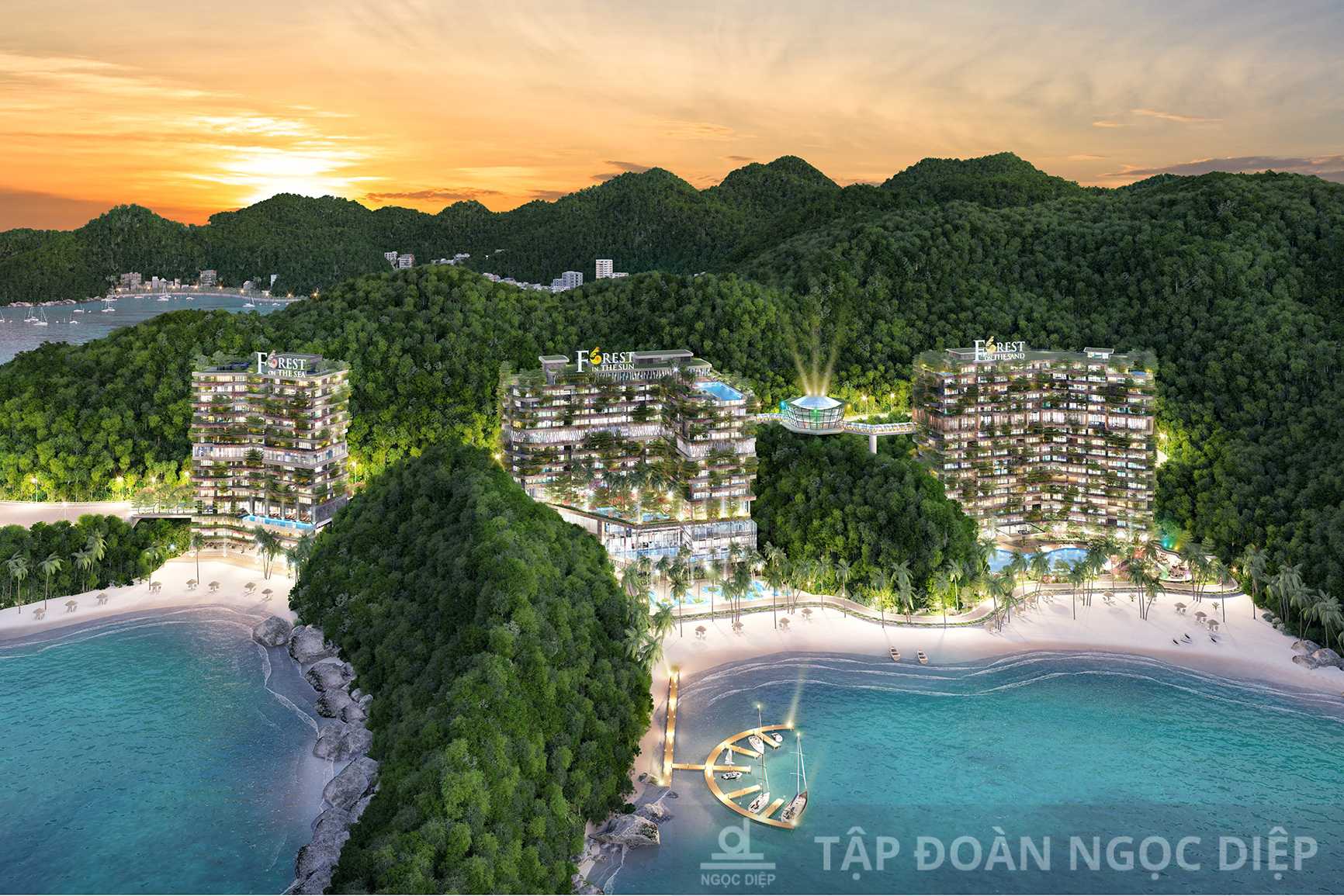

(Photo: Reuters)

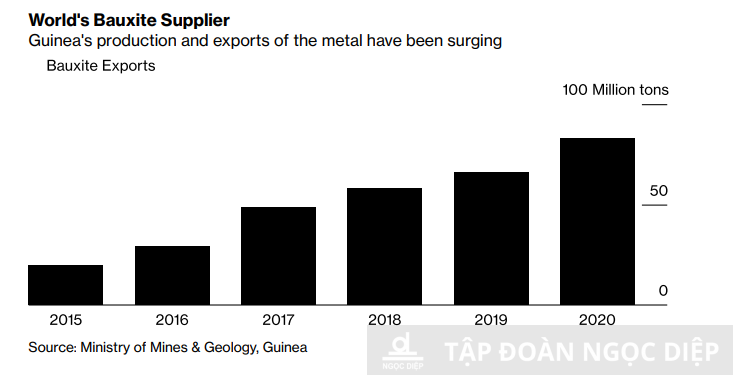

Guinea supplies about 25 per cent of the world’s bauxite, mostly to China and Russia. The country shipped 82.4 million tons of the mineral globally last year, according to government data. Guinea is China’s largest source of bauxit. In the first seven months of this year, Guinea supplied China with 55 per cent of its bauxite supply, according to analysts at ING. China, in turn, is the world’s largest producer of aluminium. Rusal, the world’s third-largest aluminum producer, owns three bauxite mines in the country, which accounted for 50 per cent of its total supplies last year.

Guinea exported 82.4 million tons of the mineral globally last year (Photo: Bloomberg)

The unrest did not have any immediate impact on bauxite operations, however it extended a rally in aluminium prices to multi-year highs and boosted shares in aluminium producers.

Aluminium prices have hit decade high due to supply concerns (Photo: Bloomberg)

Aluminium prices on the London Metal Exchange rose as much as 1.8% to $2,775.50 a ton, the highest since May 2011. In China, futures jumped as much as 3.4% to the highest since 2006. Shares in Russian aluminium producer Rusal rose 4 per cent in Moscow on Monday before edging back, while those of Aluminum Corporation of China were up 5 per cent on the back of higher aluminium prices. In Europe, shares of Norsk Hydro rose 5 per cent in Oslo.

The events in Guinea are “adding fuel to the fire, not least since the whole bullish narrative for aluminium is about tight supplies”, said Julius Baer analyst Carsten.

An aluminium factory in China (Photo: Aluminium Insider)

Aluminium prices have also been fuelled by production cutbacks in China, where the Communist party is increasing scrutiny over highly polluting industries as it looks to meet its climate goals. A report from Bloomberg on Monday said southern Guangxi province may order production cutbacks in aluminium and steel in a bid to reduce pollution.

Aluminium production in China has already been hit by electricity shortages over the summer, especially in south-west Yunnan province. A drought in China’s Yunnan province has cut the area’s hydropower output, causing shortages and prompting local government to ask aluminium smelters to reduce their usage.

Aluminium prices have risen by about 38% this year. Goldman Sachs increased its 12-month price target for aluminium to $3,200 a tonne.

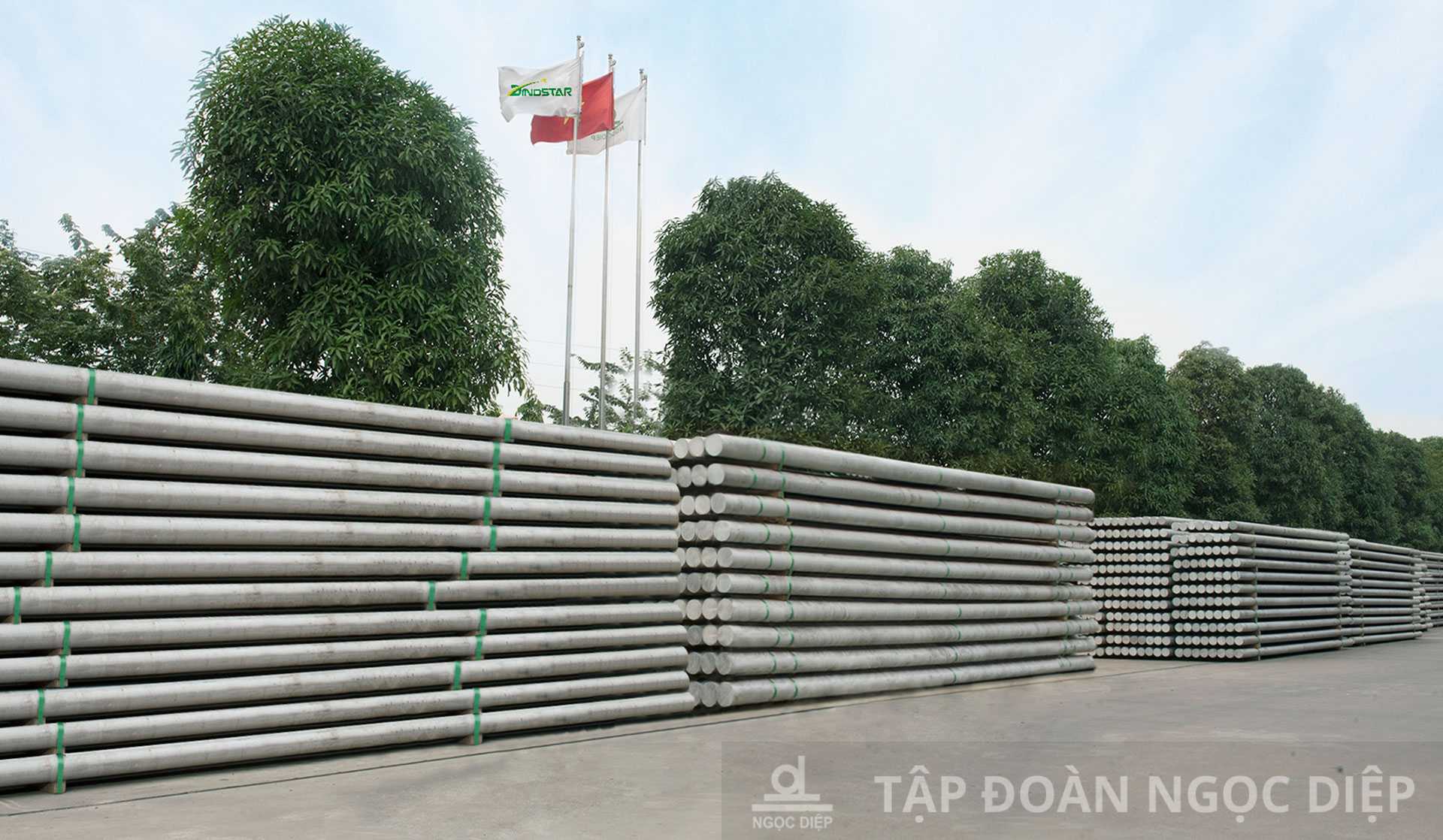

Abundant reserves of Ingot, aluminum raw material, of Ngoc Diep Joint Stock Company

(Photo: Ngoc Diep Group)

Ngoc Diep Aluminum Joint Stock Company with the Dinostar Aluminum brand, the top aluminium manufacturer in Vietnam, constantly monitors market in order to anticipate and respond appropriately, bringing the highest benefits to customers and partners.

Source: Financial Times, Bloomberg, Reuters

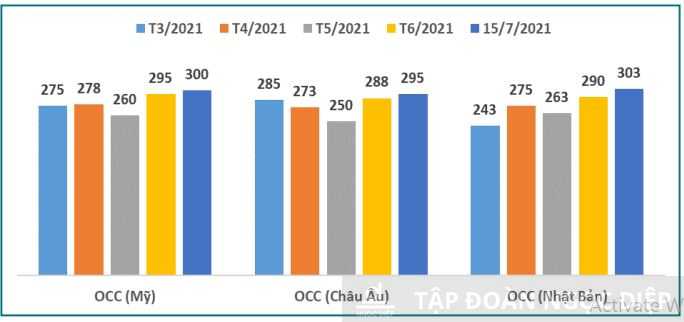

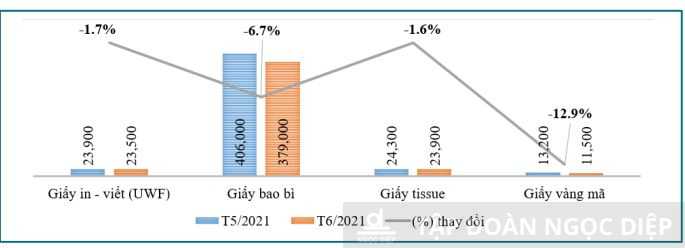

Production output in June 2021 compared with May 2021. (Source: Vietnam Pulp and Paper Association statistics)

Production output in June 2021 compared with May 2021. (Source: Vietnam Pulp and Paper Association statistics)